Description

Getting away for another weekend camping trip? Hauling the boat out to that new fishing hotspot? Driving up to the cabin for the annual hunting trip? No matter where you’re headed or which toys you’re towing along for the ride, Bring It® with CURT!

CURT class 2 trailer hitches are perfect for adding storage space to your vehicle or towing a small, light-duty trailer. They are typically found on full-size cars, crossovers and minivans.

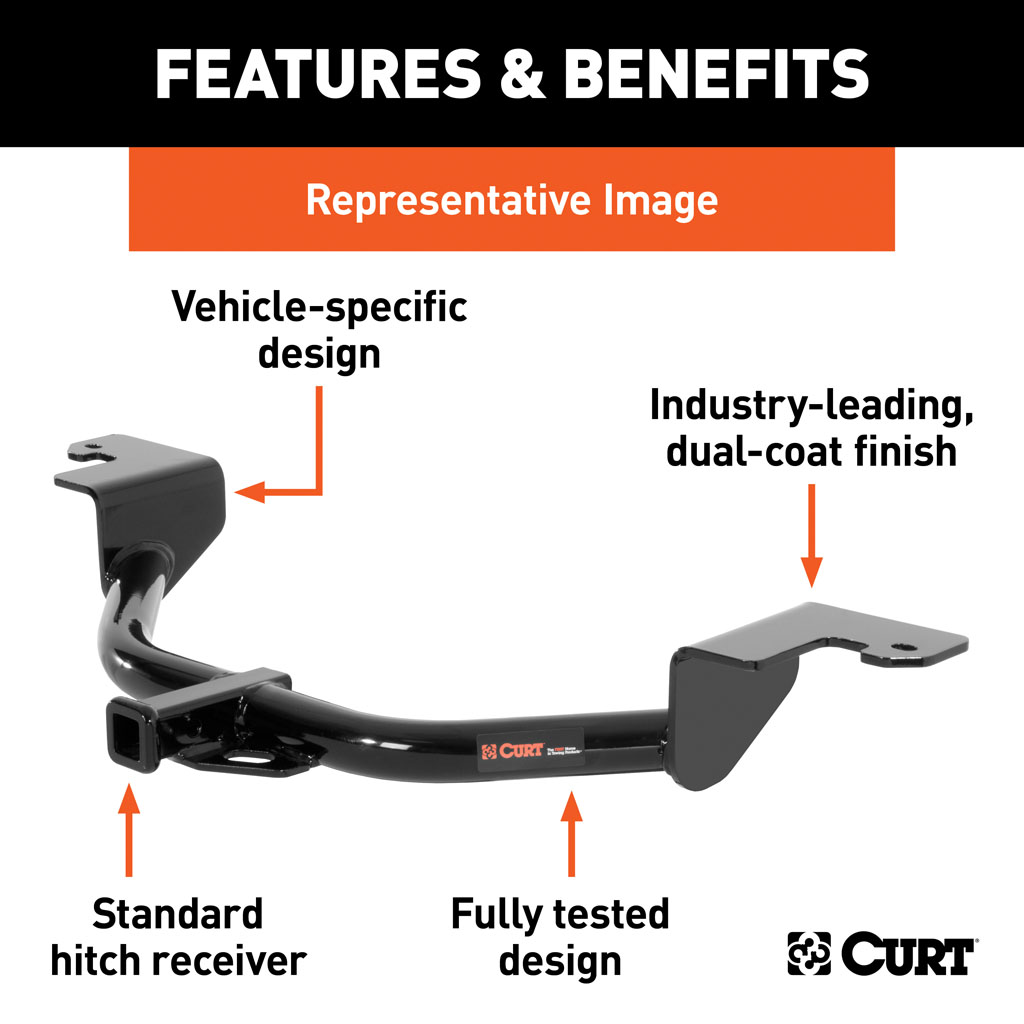

URT class 2 hitches are made vehicle-specific. This means that each and every towing hitch is designed to custom-fit a specific vehicle application. This ensures dependable towing strength, an integrated look on the vehicle and a streamlined installation. This particular class 2 hitch is made for a custom fit on certain years of the Jeep Compass (to verify vehicle compatibility, see application information or use the Vehicle Lookup).

This Jeep Compass hitch is rated to tow up to 3,500 lbs. gross trailer weight and 350 lbs. tongue weight. This makes it an excellent choice for towing a small utility trailer, popup camper, boat trailer and many others (never exceed the lowest-rated towing component). It is also the ideal option for adding cargo space to your vehicle with a hitch-mounted cargo carrier or bike rack. Like all CURT custom hitches, this class 2 hitch is stringently tested for safety. We want to ensure you can tow with confidence wherever your destination might be. We test our hitches in-house at our Detroit, MI engineering facility, according to SAE J684.

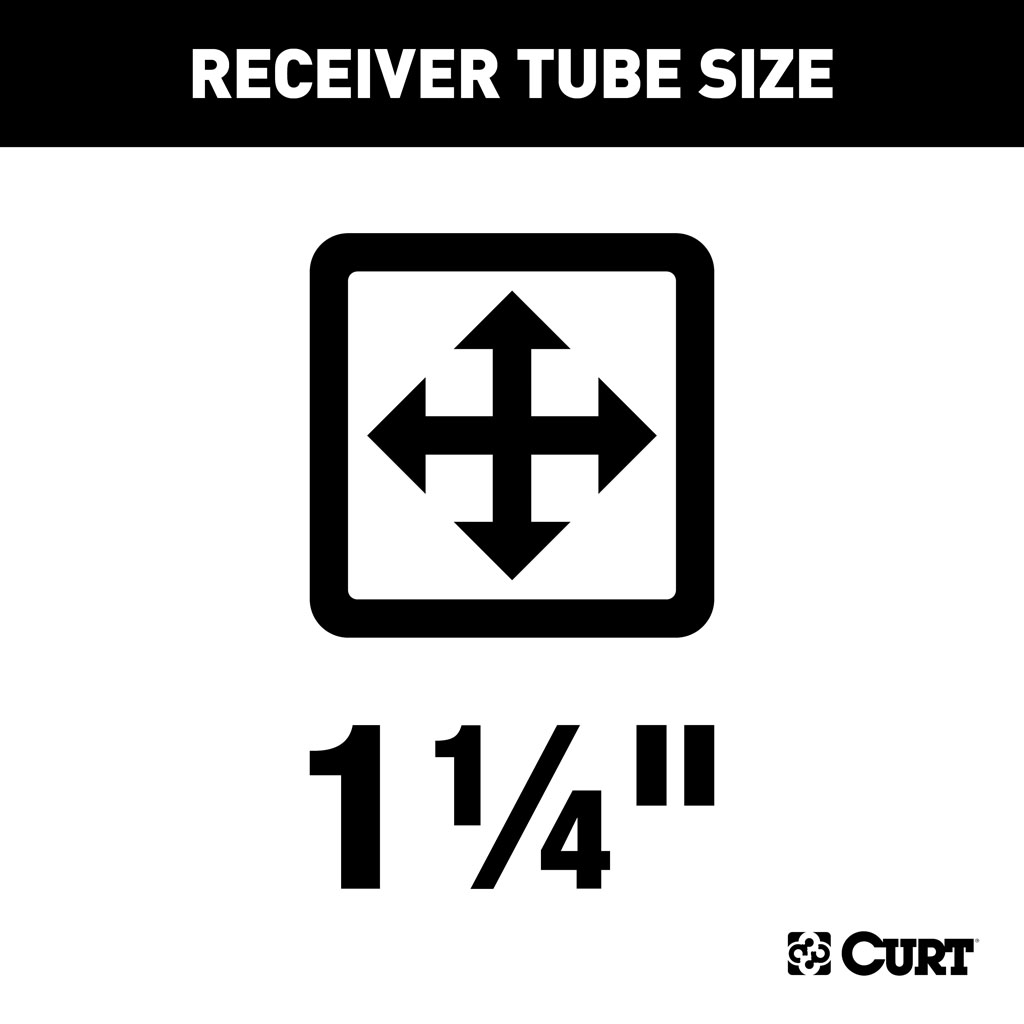

Like our class 1 hitches, this class 2 tow hitch comes with a 1-1/4″ x 1-1/4″ receiver tube opening. This industry-standard 1-1/4″ receiver is able to accept any ball mount or other hitch accessory with a 1-1/4″ shank. It can also accept a hitch tube cover when not in use to keep the hitch receiver clean and dry.

From class 1 to class 5, all CURT custom trailer hitches are designed, manufactured, finished and tested to ensure maximum performance and longevity. We employ hands-on engineering techniques, using real vehicles, to fully optimize our hitch designs. We fabricate and weld our hitches using a combination of manual and robotic processes for maximum efficiency and accuracy.

Finally, we finish our towing hitches with a unique co-curing process, using liquid Bonderite® and highly durable gloss black powder coat. Each hitch is fully immersed in the Bonderite®, covering it inside and out with a rust-resistant layer. Then, the powder coat is applied over the top of that. The two finishes are cured together to create a shield of industry-leading rust, chip and UV protection.

To ensure quality through every step of the manufacturing process, all CURT custom-fit receiver hitches are made right here in the USA (may include imported hardware) and are backed by a limited lifetime warranty.